Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-21-54321355

Brand: JUMP

Applicable Industry: Manufacturing Plant, Food &Amp; Beverage Factory

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, Uae, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Algeria, Pakistan, Germany, Egypt

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc, Motor

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Condition: New

Video Outgoing-inspection: Provided

Machinery Test Report: Provided

After Warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Warranty Of Core Components: 1 Year

Marketing Type: New Product 2021

Usage: Industrial Usage

Showroom Location: Algeria

Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops, Other

Year: 2021

Local Service Location: Uzbekistan

Power: 3kw

Function: Multifunctional

Brand Name: JUMPFRUITS

Dimension(L*W*H): 2100*1460*1590mm

Color: Customers' Requirements

Warranty: 1 Year warranty,life-long aftersell service

Capacity: 100kg/h to 10T/H treatment capacity as customer require

Raw Material: 304 Sainless Steel

Feature: turnkey solution

Type: complete project for chip engineering project

Application: building chips processing plant

Name: customized chip processing line

Product Name: potato chip frying machine

Item: potato chip frying machine

Place Of Origin: Shanghai, China

Voltage: 220V/380V

Certification: CE/ISO9001

Weight: 800 KG

Packaging: Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion. Fumigation-free package helps the smooth customs clearance. The big size machine will be fixed in container without package.

Productivity: 500kg-5T

Transportation: Ocean

Place of Origin: Shanghai

Supply Ability: 20 Set/Sets per Month potato chip frying machine

Certificate: ISO CE

Port: shanghai port

Payment Type: L/C,T/T,MoneyGram

Incoterm: FOB

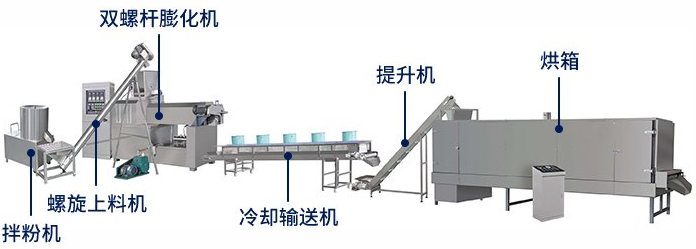

For Turnkey Food Beverage Production Line/Can Food Machinery/ Fruits Juice Machinery/Tomato Sauce Machinery/Fruits Jam Machinery/Milk Yogurt Machinery Please Contact us 1. Equipment introduction: Frozen French Fries Processing Line, french fries, as a snack that everyone loves, are deeply loved by consumers. The processing of french fries requires the matching of a variety of equipment to produce large quantities of french fries using an assembly line. Matching the form of the assembly line, the continuous work efficiency is high. Peeling a lot of potatoes is an important part of French Fries Processing Line. Peel quickly and evenly.The supporting equipment required for the quick-frozen french fries processing equipment are: potato soaking washing machine -- potato washing and peeling machine -- potato cutting machine -- potato destarch washing machine -- potato blanching machine -- potato cooling machine -- draining machine -- air dryer -- fryer -- oil drainer -- spreader -- quick freezer -- vacuum packaging machine, etc.

The raw material of french fries is potatoes. During processing, the potatoes need to be cleaned and peeled as the first step of processing. Potatoes have special peeling equipment for peeling and processing large-volume potatoes to ensure processing efficiency. The size of the equipment can be customized according to the actual processing needs to ensure the processing needs of large output. The operation of the continuous auger makes the potatoes move forward continuously and ensures the large output of continuous processing.

We will wash the potatoes before blanching, and use the washing water to rinse the starch on the surface of the potatoes to prepare for the blanching of the next process. The blanching temperature and blanching time can be automatically controlled to ensure blanching efficiency and blanching quality. The blanching equipment can be used for blanching a variety of products, at a specific temperature and a specific time.

In the frying process of potato strips, the blanched potatoes are transported to the fryer, and after frying for a certain time and temperature, they are output along with the conveyor belt.

Drainer: The fried potato fries can be directly transported to the drainer to drain the excess oil on the fries through regular vibration.

Spreader: It can quickly dissipate heat and drain oil.

Features:The equipment can be customized according to the actual processing requirements. The equipment is made of food-grade 304 stainless steel, which fully meets the national food-grade standards and can be used safely. Every detail of the equipment is made of 304 material. After more than ten years of use, it will not change color, will not rust, and will not corrode. Our company promises to guarantee the quality and quantity of the equipment. Lifetime service. Welcome to our company for on-site test inspection. The equipment can be customized according to actual needs, and suitable equipment can be customized for you.

Potato chip line processing process:

Cleaning and peeling----selecting----slicing----rinsing----blanching and color protection----air-drying and draining--frying--air-drying and draining oil--seasoning-- --Package

French Fries Processing Line

Product Categories : Snack Food Production Line > Automatic French Fries Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.